TRL conducted a series of motorcycle helmet roll-off tests several years ago to determine which factors are likely to be causative of helmet loss through roll-off in a collision. The results were published as a TRL project report, Helmet Retention Report in 2014 https://trl.co.uk/reports/PPR689.

This report showed that helmet size and internal shape were important factors in helmet ejection. The tightness of the chin strap was critical to the force required for loss through roll-off.

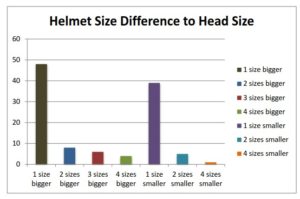

At the same time TRL carried out a remote survey of circa 600 motorcycle helmet users to see what factors influenced their helmet choice. This data showed that a large number of helmet users were purchasing helmets through the internet without first determining that they were of the correct size or internal shape, with the potential for increased helmet loss. This is a concern that has been expressed by a number of research studies.

To further this research determining how helmet fit (subjective) relates to helmet retention (objective), we are planning to scan the heads of a limited number of actual and potential helmet users, from which headforms conforming to their head shapes will be fabricated. These headforms will be used on the TRL roll-off headform test rig with a range of helmets, to provide the objective data, and the individuals will try on the test helmets to offer a subjective view of fit.

We will also repeat the remote survey of helmet choice and fit to see whether the results of the previous survey are still valid.

The aim of this further study is twofold.

The first aim is to try to provide a better form of advice to prospective helmet users to reduce the potential for helmet roll-off.

The second is to act as a technology demonstrator, to illustrate how current scanning methods can be employed beyond mere post-collision measurement. A number of other researchers have used this technology to demonstrate that there is a demonstrably wide range of head shapes, but have not taken that knowledge further.

The means of transferring the scan data to a solid test headform has yet to be confirmed, but it would be beneficial to use advanced technology, such as automatic machining and/or 3d printing for this project.