A rotating wheel stores a large amount of energy, both rotational and linear, and can cause a huge amount of damage and injury if it separates from a vehicle.

The attachment of a wheel, or wheel pair, to a hub, is an example of a bolted joint that is subject to a wide range of force inputs.

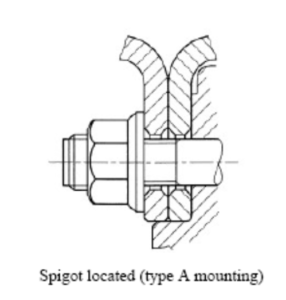

Figure 1 – A perfect bolted joint for a wheel pair

A secure bolted joint depends on a number of variables which must be satisfied if it is not to loosen. For a wheel those variables are:

- quality of the joint

- number of wheel nuts

- the tightening of those wheel nuts

- service conditions.

Often, the wheel fitter is blamed for wheel loss. Whilst this may be true in some cases, wheel loss still occurs when the nut tightening has been conducted correctly and verified by an observer. This demands that the quality of the joint itself is examined in detail.

Vehicle wheels are subject to both static and time-varying forces. Investigations conducted by TRL have shown that wheel distortion, both large- and small-scale, are responsible for many wheel losses, showing that the in-service use of the wheels is far from the perfect bolted joint shown in the diagram above.

Lateral forces on wheels are responsible for large scale distortions of the wheel disc, leading to the surface no longer being flat. Small-scale distortions are often as a result of the bolted joint itself, again causing non-flat contact surfaces within the joint.

Figure 2 – Circular fretting marks showing the presence of small-scale distortion at the bolted joint

Along with the variables listed above, any investigation into wheel loss should concentrate on the physical condition of the wheel disc to ascertain whether there is either large- or small-scale distortion present. TRL have developed several methods to identify and examine both types of distortion, using a combination of inspection techniques, measurements and physical testing. These have been used to investigate a number of catastrophic wheel loss incidents where others have been unable to determine the real-world reason for the loss.

Figure 3 – investigating distortion

There are no industry standards for acceptance of distortion and many operators, fitters and service companies are not trained or tasked to determine whether distortion is present. Aside from the safety issues associated with a single wheel loss, commercial vehicle operators are at risk of loss of their Operators License for repeated losses.

Along with investigating specific instances of wheel loss and their causes, TRL are also commissioned by fleet operators to review Standard Operating Procedures and carry out observations and testing on-site, to assess the adequacy of procedures as well as staff adherence to these, in real-world situations.